Phenyl vinyl silicone oil

- USI

- CHINA

USi-OP40

Features

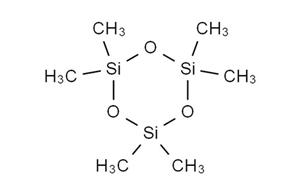

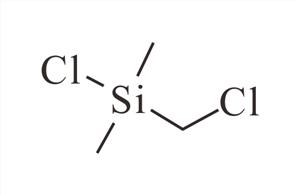

Vinyl-terminated methyl phenyl silicone oil is mainly used in the preparation of additive liquid silicone rubber, because of containing phenyl functional groups, improve the resistance to high and low temperature, radiation resistance. It is designed for the manufacture of high-power high-refractive-light-emitting devices with silicone encapsulated plastic, optoelectronic, electronic and microelectronics industries. It is mainly used in the manufacture of high-power, high-power, Lens and the user to develop other uses, the product after curing the film soft and hard adjustable, high refractive index, good light transmission, with a strong solvent resistance, water resistance, ablation and radiation resistance, but also has High temperature performance, no sticky and other advantages. The products made with anti-aging, anti-ultraviolet performance and long-term use of non-yellowing of the excellent characteristics. Its structure is as follows:

(CH2 = CH2) (CH3) 2SiO [(CH3) 2SiO] m [(C6H5) 2SiO] nSi (CH3) 2 (CH2 = CH2)

Technical Specifications

Appearance: colorless transparent oily liquid

Viscosity 25 ° C, mPas: 20-1000

Refractive index (25 ° C): 1.41-1.47

Phenyl content (mol)%: 5-30

Vinyl content (mol / 100 g): 0.01-0.1

Volatile (150 ° C, 3 h)%: ≤ 3

Other specifications can be produced in accordance with the specific requirements of customers.

Application

1, Mainly used in the manufacture of high-power LED with silicone packaging plastic, optoelectronics, electronics and microelectronics industry potting, sealing, bonding and coating, high light transmission, high hardness lenses.

2, Other applications to be developed.

Usage and dosage

According to the vinyl content, adding the corresponding cross-linking agent, catalyst, dubbed liquid silicone rubber used.

Precautions

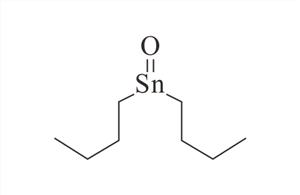

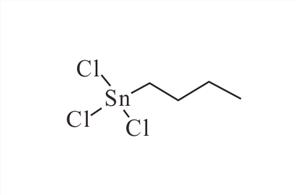

The use of the process, the whole process of exposure to nitrogen, phosphorus, sulfur, polyvinyl, peroxide, lead, tin, cadmium and other metal compounds, to avoid silicone rubber catalyst poisoning caused by incomplete curing.

Packing and storage

Packing: 25kg, 50kg, 200kg plastic drum

Storage: sealed storage, storage at room temperature for 12 months.

Transportation: This product is non-dangerous goods, according to general chemical transport.