Amido silicone oil

- USI

- CHINA

USi-O13

Introduction

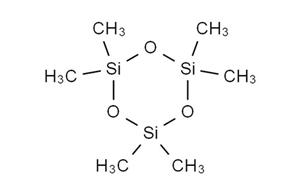

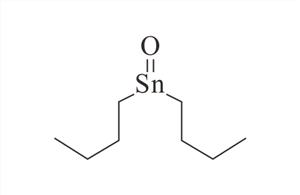

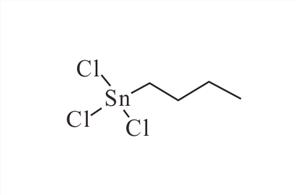

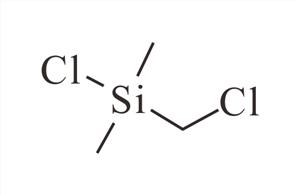

USi-O13 amino silicone oil is a kind of amino-modified polyorganosiloxane with diamine groups on lateral chain. The molecular structure is R1(CH3)2Si 0[(CH3)2Si 0]m [(R2)(CH3)Si 0]n Si(CH3)2R1. In this structure, R1 is methyl or oxhydryl; R2 refers to amino-alkyl with primary amraine and secondary amine. The product has quite powerful absorption to human hair and textile fiber, such as cotton, wool, silk, hemp, etc. In addition, it can be closely bond with the active groups in hair or fiber and its surface will form a layer of firm protective film, which will produce lasting soft, smooth and glossy sense and makes it wear resistant, bending resistant and washable. It passed the provincial appraisal in 1997, filling in the blank within the province and reaching the advanced level in China.

Specification

Appearance: Clear to pale yellow liquid

Viscosity (25℃,cp): 200~100000

Specific Gravity(25℃): 0.965~0.989

Refractive Index (ND25): 1.394~1.426

Amino Content: 0.5~0.6

Applications

1. Applied in high-grade hair shampoo to make the hair softer, smoother and glossier, obviously reduce the carding and anti-static and washable.

2. Applied for treating the textile fiber, such as cotton, wool, hemp and silk to make them soft, smooth and elastic. Thus it is the ideal material for making hair shampoo and high-grade textile softener.

3. Applied for glazing and protection of wooden and leather furniture and floor.

4. Other applications unexhausted and to be developed.

Usage & Dosage

1. When applied in hair shampoo, the amino silicone oil shall be emulsified by non-ionic or amphion surfactant and then be added into hair shampoo, hair conditioner, nutrition hair oil, mousse, etc. according to the solid content standard of 0.5~1%. As the emulsified silicone emulsion, USI-O13 amino silicone oil emulsion can be directly used.

2. When applied to soften the textiles, such as cotton, wool, hemp and silk, it shall be emulsified firstly; then add the amino silicone emulsion to the softening emulsion and mix up; then it can be used to soften the textile. The dosage is decided according to the softened textile and technical requirement. Generally, it is 0.3~1% (solid content) of the water.

Attentions

USi-O13 will encrust or takes on cross-linking curing when exposed in open environment too long and have viscosity change or cross-linking tendency if mixed with acid base matter. As it will become yellow in high temperature, it is not suitable for treating white or light textiles.

Packaging, Storage & Transportation

1. The silicone oil and emulsion shall be sealed in clean polyethylene plastic drums or iron drums lined with plastics and are forbidden to contact with strong acid or alkali materials.

2. It shall be stored in ventilated, cool and dry places at room temperature of 4~35℃.

3. It shall be transported as nontoxic and non-dangerous goods.

4. Expiry date: 1 year. It is applicable if qualified after one year.